Understanding the common pitfalls of creating indoor and outdoor architectural signage before you begin can save headaches for you and your customers.

Your clients depend on architectural signage to do more than communicate a message. Architectural signage must also help build the brand name of the company it serves.

That makes architectural signage one of the more challenging assignments in the industry because success depends not only on precision craftsmanship but also on cutting edge design and carefully selected materials that will best represent the finished product.

Understanding the different needs for indoor versus outdoor signage, such as durability, lighting, regulations and installation can help your company overcome the myriad of architectural signage obstacles. Equally important, however, is communicating with your customers. The key issues with customers are timing and cost. Discussing realistic expectations every step along the way using specs, photos and illustrations saves time and money in the end.

Should My Company Venture into Architectural Signage?

But before you even enter into architectural signage, experts warn that this sector of the industry typically requires much more attention to detail than electrical signage.

“The thing that sinks a lot of people is attention to detail,” said Warren Casteel, president of Casteel & Associates, Inc., a custom architectural signage firm in Dallas. “The paperwork and detail orientation required is far, far greater in the architectural graphics business than in the electric signage business. “

Casteel said that if you are not detail oriented and willing to do lots of paperwork and documentation then the electric signage industry is probably a better route for your company.

Planning for Precision and Durability

Creating quality architectural signage, then, means understanding the details and planning for the obstacles involved. The challenges are somewhat different depending on whether you are creating signage for indoor or outdoor use.

“The challenge on indoor signage is to have a degree of precision that is unsurpassed,” said Casteel. “We actually measure things for interior signage in thousandths of an inch. We set up saws with digital calibers.”

With exterior signage the tolerances do not have to be quite as precise, but then there are other challenges that are just as significant, such as weather conditions.

“Interior signs are in air conditioned environments but with exterior items we have to worry about sunlight, humidity, heat, cold and so on,” said Casteel.

Indeed, creating exterior signage requires more durable materials that can withstand strong weather conditions, but that’s not to say that interior signs are exempt from these concerns.

“There is a subtlety, too with indoor signage,” said Bob Silverstein, co-owner of FASTSIGNS of Schaumburg in Illinois. “If it is in direct sunlight you have potential fading issues. You have to choose materials that will be fade resistant.”

Understanding How Lighting Impacts Display

Fade resistant materials are important to protect both indoor and outdoor architectural signage from the sun, but understanding the impact of ambient lighting is also a key challenge for sign makers.

“When you are inside you basically have the same light all the time,” said Silverstein. “You can control, shape and mold and form that light however you want. Whereas outside, 8 a.m. is different than 8 p.m. January is different than June. Those are all exceedingly important.”

Silverstein added that if you work with shiny surfaces you have to be concerned with the reflections of the sunlight off the ground and the sky because they will affect how the sign looks as the season and weather changes.

One of his customers learned this the hard way. The customer ordered a pile-on sign that was 17-feet vertical by 17-feet horizontal. The design called for display of the company’s logo in a brush stainless steel set against a black polished granite background.

“We had recommended getting away from the black granite and going with a red granite,” said Silverstein. “Based upon our experience we knew that on gorgeous sunny days the ground reflections would be such that you would not be able to see the stainless steel on the black granite. It got lost. So we recommended two alternatives and they declined. They had absolutely miserable signs.”

Choosing the Right Materials for the Job

Between durability and lighting concerns, choosing the right materials for architectural signage can be a major obstacle for the novice. And making clients understand these various issues can be a challenge in itself. Silverstein’s example illustrates the importance of choosing the right material for the job. Black granite may have been perfect in different conditions, but in this case lighter granite would have produced better results.

Experts say there are some materials that quality sign makers should avoid altogether for sake of customer satisfaction.

“There are some of the lower end plastic products that we do not like to work with because the customer might not end up getting the look that they wanted or they think it ends up looking a little bit cheap when we’re finished,” said Casteel. “For example, we try to stay away from some of the laminated plastics that are made to look like metals.”

Special Considerations in the Design Phase

The actual “look” of a sign is the focus of most of the customer’s attention. The primary challenges in the design phase is coming up with a look that the customer wants and helping them choose materials while staying within their budgets. It is important to choose your materials in the design phase so that you can prepare for any special requirements, such as lighting, mounting, or curved walls.

“We have to work with interesting mounting because normally the customer wants no exposed mounting hardware at all,” said Casteel. “There are times that we do mounts when it is not even evident that there are mounts. When we do letters, for instance, that stand fairly far off a wall.”

Casteel also works with curved walls which requires the signage to be curved as well. “Before the logo is manufactured, the plate from which they were manufactured has to be pre-rolled so that the actual letter forms then would follow the curvature of the wall,” he said.

Regulatory Requirements and the Customer

After the materials are chosen, the design is complete and the sign is ready to display there are still two key obstacles for the architectural sign maker: regulations and installation. The challenge here is not so much meeting the specs but convincing the customer why you have to.

“Communities have regulations on exterior signage,” said Silverstein. “We have a lot of customers who don’t think it applies to them, but it does. It’s real important to work with customers in terms of regulations on the exterior signage.”

Casteel agreed. Community regulations are one thing, he said, but getting clients to deal with the Americans with Disabilities Act (ADA) is perhaps the biggest obstacle of all.

“ADA has been around for about 10 years now and we’ve learned how to produce the product and design and implement it, but customers are very resistant sometimes and say it doesn’t make sense,” he said.

Outdoor versus Indoor Installation

In terms of installation, the sign maker also has to deal with underground utilities like phone and power and fiber optic networks. That means special permits that can slow down the process.

“You have to get permits or it comes back to haunt you,” said Silverstein. “Then there’s weather conditions again. Is the installer going to bite the bullet and rent the equipment necessary to logger into frozen ground if necessary?”

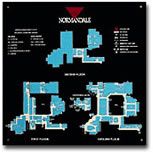

When it comes to interior signage the challenges are altogether different. Other than ADA, there typically are no regulations. Rather, the obstacle is location. Interior architectural signage is typically on a wall and sometimes there is not a suitable wall behind the reception desk, for example, or in the direct line of sight from the elevator.

“Companies like putting their logo where you can see it as soon as you get off the elevator or as you are walking down a corridor and if that reception area does not have a suitable wall for displaying the sign then you have to work around it,” said Silverstein.

Since sign makers are often called in after the customer has built out the space, background for signs can create a challenge. Color and texture of walls, lighting or the pattern on the wallpaper can be distracting. Sign makers have to get creative to find appropriate solutions.

Silverstein described one company that wanted a sign behind the reception desk. But the lighting was terrible.

“No matter what we did we couldn’t get a good look for the sign because of the way the wall was finished,” he said. “What we wound up recommending is taking the material that they made the reception desk out of and using that for the wall. It gave it a super look and tied in the desk to the wall. It actually made the wall pop out very nicely from the rest of the surroundings.”

Communicating with the Client

Weather, lighting, materials, design and installation aside, the most common pitfall has nothing to do with creating architectural signage from the technical standpoint and everything to do with communicating effectively with the client. Other than design, most customers are primarily concerned with two things: cost and timing.

“Exterior signs are always more expensive than corresponding interior counterparts,” said Silverstein. “The cost is always more than what the customer thinks.”

And since the cost is always more than the customer thinks it is important to calculate all the charges in advance so there are no surprises later. The danger for novice sign makers is pricing too low.

“The biggest pitfall in the sign industry in general, especially in architecture and graphics, is trying to be the low price leader,” said Casteel. “Typically you can not always be the lowest price guy and always produce quality product. Quality product will take you a lot further down the road and build reputation far better than will be the lowest price guy in every situation. A lot of companies that are new tend to feel they have to have the lowest pricing. You don’t always have to be there. You have to have a fair price. You can’t be the highest either.”

Other than pricing, timing issues are one of the biggest pitfalls for the architectural sign maker. Many customers don’t take regulations and installation procedures into account during the planning process.

“Outdoor signs always take more time than what the customer thinks,” said Silverstein. “We talk in delivery time being after all the permits are obtained. Indoor signs go faster because fabrication methods are not as elaborate, there is no preparation of the site and there’s no regulations or permits to get signed off on.”

Meeting and Exceeding Client Needs

Experts say communicating with the client goes beyond talking. In order to truly understand what the customer wants sign makers should take advantage of digital photography and mock-ups. This saves time and money in the end and helps ensure a satisfied customer.

“Be very thorough in selling and creating specs,” said Silverstein. “Don’t rush to give a quick quote. Work very closely with the customer to come up with a good solution to their sign problem.”

This means photographing the site and providing proof photos to help the customer envision what the finished product will look like. Illustrations are also a valuable tool.

“Probably the most important thing is that once we get a job we make sure to do a lot of homework up front in terms of where the sign is going to go, what it is going to look like and regulations,” said Silverstein. “We try to remove any surprises to either ourselves or the customer. Most people would like to have something done right rather than have something wild with a lot of extras at the end. And that’s what we try to achieve.”

As seen on signindustry.com