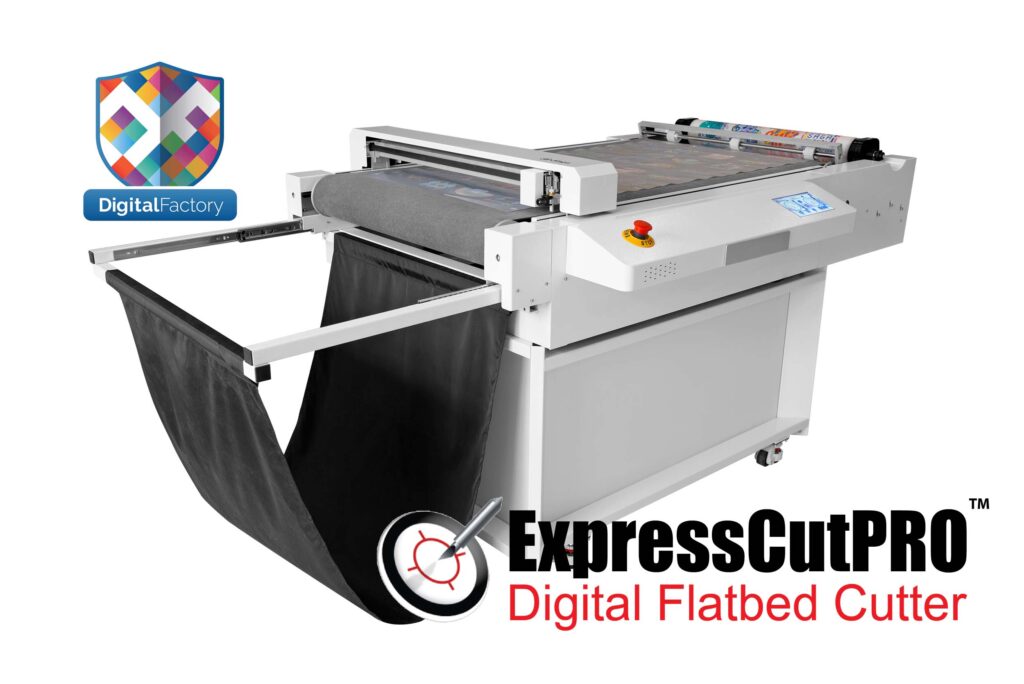

Supply55, Inc. is pleased to announce ExpressCutPRO is now supported by CadLINK Digital Factory.

The integration of CadLINK Digital Factory into the cutting workflow of ExpressCutPRO provides the user with a robust streamlined application environment when printing and cutting: DTF (direct to film), UV DTF, labels, stencils, apparel patterns, engineering patterns and other non-woven material.