Did you know NEPATA also produces color card samples for vinyl, foils and HTV in addition to building converting equipment?

Color sample cards for foils, vinyl and HTV are extremely important for sales in the advertising technology industry. And yet they are gradually disappearing because film manufacturers find production too complex. This is where NEPATA can step in: with a unique production process to produce color strips at low unit costs. And with an all-round carefree service right through to the finished sample card.

As a service provider, we produce individual color sample cards and color strips – automated and cost-effective. In this article, I’ll explain why it can be worthwhile for you as a film manufacturer or wholesaler to place the production of color strips or color cards in our hands.

Color charts for foils – foil trade and advertising technology cannot do without them

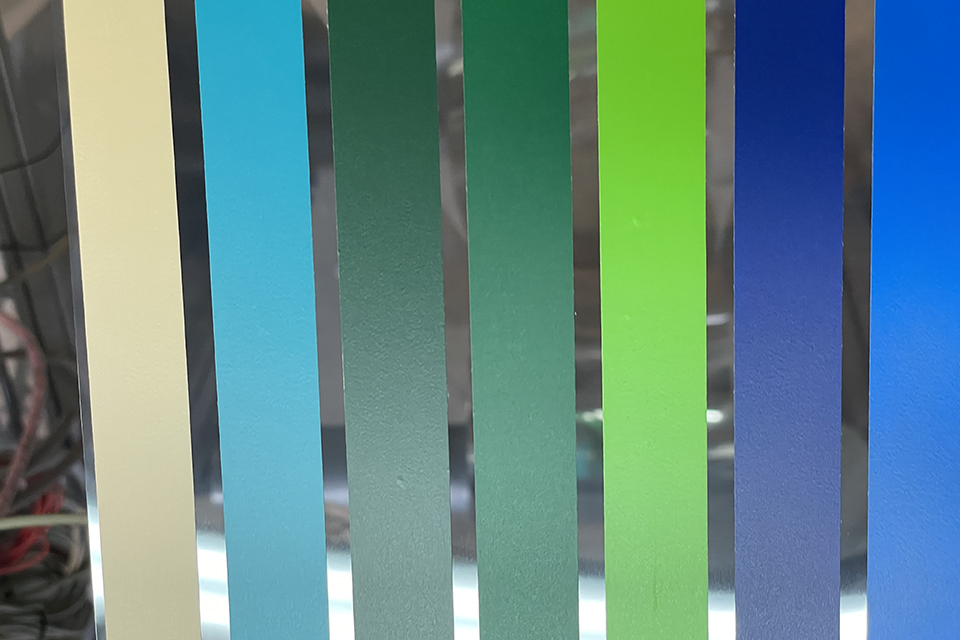

Color sample cards are extremely important for film manufacturers and dealers in the advertising technology sector in sales: this is the only way customers can make an accurate choice from the huge range of decorative films, car wrapping films, flock films, flex films, etc. An advertising technician is supposed to put stickers on a craftsman’s new van. Now he has to decide: Which Oracal shade best matches the company logo? Or would a plotter foil from Aslan, Mactac or Arlon fit better? A senior class wants to order shirts with neon green lettering. The creative team is now in the showroom of the textile finisher. What do you like better? The flock film or the flex film? From film manufacturer Hexis or from Politape?

Ultimately, the end customer in particular will only order what he can see and touch – because he doesn’t know anything else. However, it is impossible for the sign maker to have all the materials in stock. It is even more difficult for online shops: the color display on monitors is anything but meaningful. So how to choose the self-adhesive film for the kitchen beautification project?

Color cards are all the more important. And they should actually be available in large quantities so that they can be distributed to customers as widely as possible. Because it is certain:

Color charts increase the chance customers will access the exact slide they are viewing for their professional or DIY project. They are the central tool in foil sales.

However, the production of the sample cards is complex, time-consuming and expensive for the manufacturer. The situation in Europe is like this: you have dealers in Italy, the Czech Republic, Poland or Spain and everyone needs 300 color cards a year in their language version. Above all, however, it is the creation of the small sample strips that leads to trouble and high costs. This results in the dilemma of not being able to provide all customers with color cards because the costs would be too high. Many manufacturers are very restrictive in terms of the number of sample cards they make available – to the chagrin of dealers and customers. And for marketing campaigns, such as widespread mailings or inserts in trade journals, costs and lead times are often simply too high.

High quality, high speed – through industrial production

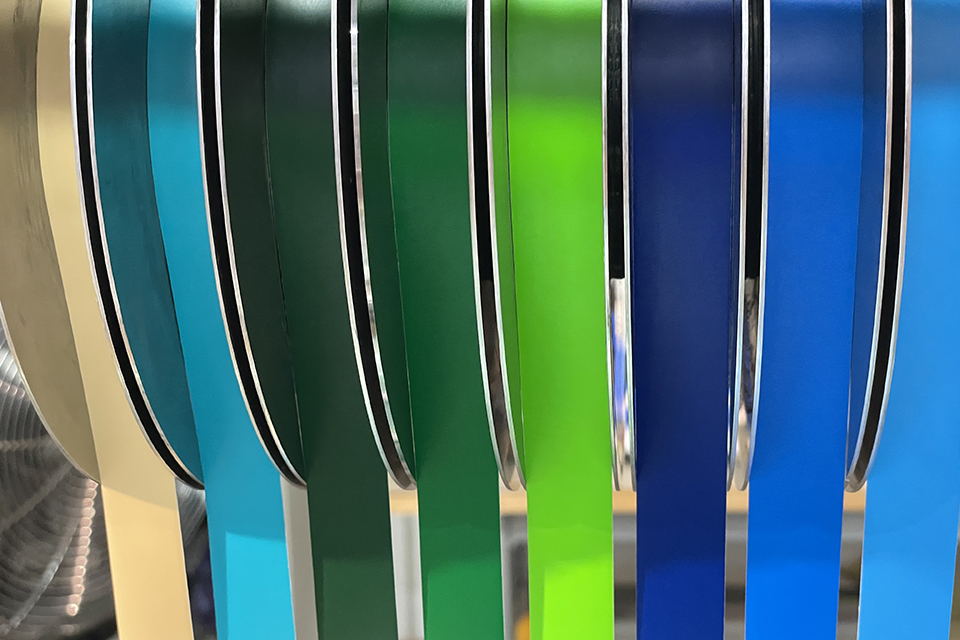

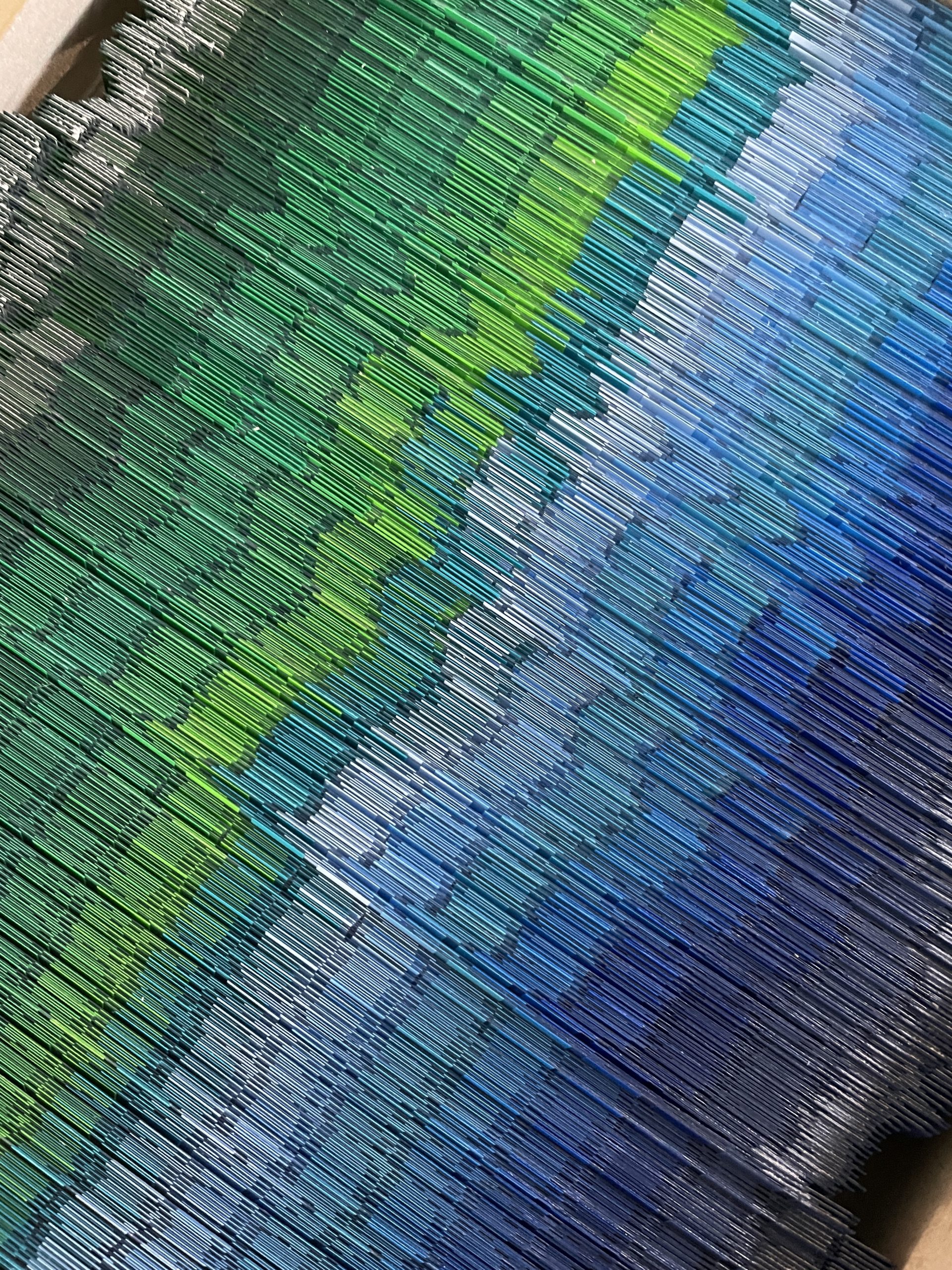

This is where we come in: NEPATA has developed a unique production process to produce color strips for self-adhesive and HTV media. With our industrial production, we can cut the colored strips quickly, in large quantities and precisely. At the same time, the automation ensures a lot of flexibility – and above all low unit costs. We developed this production process and the machines required for it 10 years ago. So it is a tried and tested system.

To make it clear at this point: we are not talking about color fans here, but exclusively about color cards, in which sample strips are glued into folding cards.

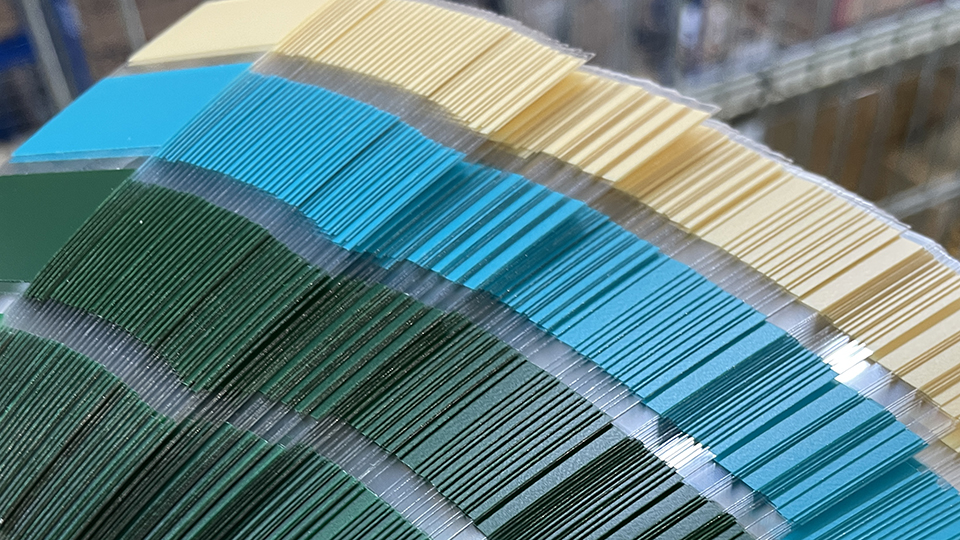

So how does the production of these color strips work? Let’s take the concrete example of one of our customers. Every two years, he has us create 5,000 color charts for his plotter foils. In addition, we receive the material in the length of 50 meters that is typical for PVC films. We cut out narrow rolls, each one is exactly 2 cm wide. Of course, a width of 3 cm would also be possible, for example.

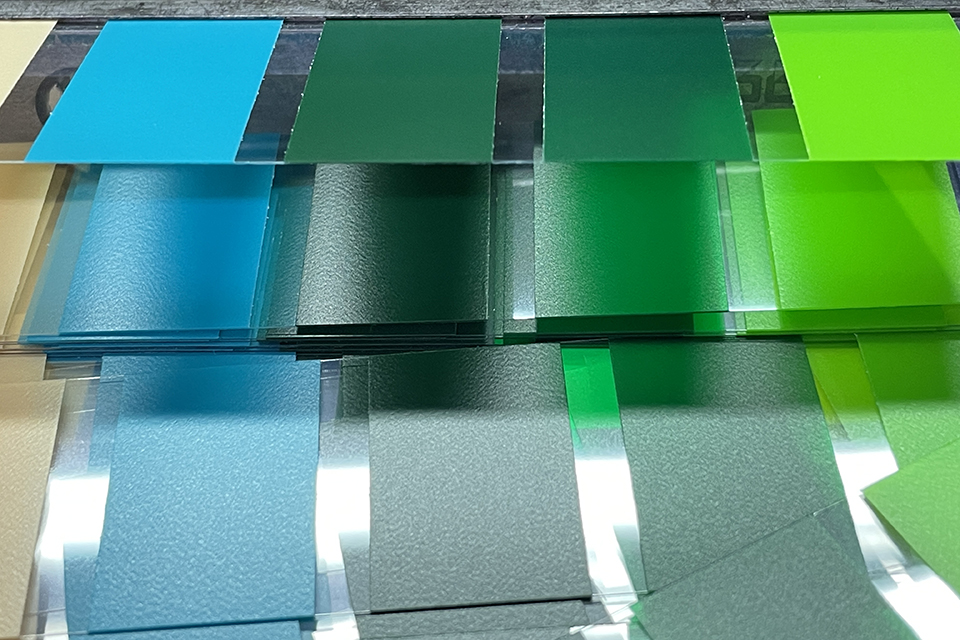

In the next step, our special machine – fully automated – pulls the silicone paper off the tapes and the plotter film is stuck onto the transparent PE film with its own adhesive. This happens simultaneously for all colors that are attached to a sample strip.

Finally, the automatic cross-cutting into the correct strip format takes place.

LOWER UNIT COSTS WITH EXPANDED PRODUCTION

Because our process is highly automated, production naturally becomes more and more profitable with larger quantities. I would say that from 500 strips of a species you can start thinking about it. Since we are not a manufacturer, it gets really interesting when there are several 1,000 pieces.

This is all the more true if you also include the source material in the consideration. For the 5,000 sample cards from our example, we need four of these 50 meter long and 2 cm wide bands of each color. This means that the mother roll is missing 8 cm in width. Since this roll can no longer be sold by the manufacturer anyway, he can use the material for even larger quantities of color sample strips or color cards.

If we get whole rolls from film manufacturers, we have enough material for tens of thousands of sample strips. In this way, all dealers worldwide could be supplied with color cards with material that they had already invested in anyway.

Now one could come up with the idea of not taking the strips from an original 50-meter roll, but wrapping short rolls and using more than just four strips. Well – in this case, the productivity benefits of our automated production process don’t really come into play. You can say: The longer, the better, i.e. the typical 50 meter rolls for PVC foils or 25 meters for textile transfer foils are simply more effective than if we process shorter run lengths.

Speaking of textile foils: As described above, our process works for all self-adhesive foils. In the case of non-self-adhesive media such as flex film or flock film, the customer first equips his films with self-adhesive. As part of our full service – more on this below – we can also take care of this, i.e. removing the top layer and applying a self-adhesive finish.

All-round service up to the finished color sample card

As a flexible service provider, we can either only take over the particularly economical production of the colored strips. Or film manufacturers use our all-round carefree service and outsource the entire handling to us. Then we take care of all the steps: printing the cards, cutting the colored stripes, in the case of flex and flock foils also the self-adhesive equipment and finally the complete packaging, i.e. gluing the colored stripes into the cards and packaging. This means that our customers do not have to organize these many steps internally or coordinate several service providers, possibly in different countries. In short: the manufacturer or distributor basically only has to take his slides off the shelf and send them to us – we take care of everything else.

Interface between film manufacturer and film trade

And it goes one step further: we can also act as an interface between manufacturers and dealers. For example, the manufacturer has us create 5,000 sets of strips – some of which remain with us. If a dealer needs new color cards, he calls us, the 300 cards are printed in his language and with his logo and the strips are made up.

The solution for foil manufacturers: Completely outsource the tedious subject of color charts – and do something good for retailers.

The service works even better if a manufacturer decides to leave the raw material to us, i.e. a roll of each type of film or color. Then we can produce the strips according to the wishes of the respective retailer: a specific selection of colors, with an individual order, etc. Our process is so flexible that it is also possible to change the printed matter and the color sample within a batch.

Another model I can imagine concerns wholesalers who have films from different manufacturers in their portfolio. You can make your own color cards (in your own layout) – and let us produce color strips with the range relevant to you. Of course, this is far more attractive than having a stamp field on a manufacturer’s card in the best-case scenario and then having to send the customer two, three or four cards from different manufacturers and ranges.

But I understand when film dealers tell me that it is too time-consuming for them to cut off pieces from 120 different films to produce the strips, just for a few hundred cards. On the one hand, because it is a lot of work, on the other hand, because the dimensions of the remaining rolls then no longer meet customer requirements. Hence my appeal once again to the manufacturers of self-adhesive foils to consider outsourcing the production of color charts. Larger quantities are simply more profitable.

Conclusion: color sample cards – and it still works

Thanks to our highly automated and therefore cost-effective production process, we enable film manufacturers to pass on color charts to distributors, dealers and customers on a large scale, to enclose them in trade journals or to distribute them to potential customers in large mailing campaigns. Other advantages of industrial production are the great precision of the sample strips and an extremely short delivery time. And the optional full service including handling of the print templates, sticking in the strips and customization for dealers relieves your own capacities even more. Hopefully you will need them elsewhere when your slides are in demand thanks to color cards.

To learn more about color card production in North America, contact Supply55, Inc. at 734-668-0755 or sales@supply55.com.