Automation, efficiency and control for your warehouse processes with the NEPATA Automatic Roll Storage System with Vertical Robot.

In almost all converting processes, roll media is stored and retrieved. This can mean thousands of rolls and hundreds of picks per day in a typical warehouse. The traditional storage of rolls and their journey to the converting area (and back) incur significant costs and loss of time, while shelving racks consume valuable space and damage the surfaces of the rolls. Nepata has the solution: automated storage systems for roll media that revolutionize the pick-up and delivery process of media from the racking area to the converting are with increased efficiency, accuracy of picked order and reduction in damaged media.

Optimize roll storage with NEPATA’s innovative, customized storage systems

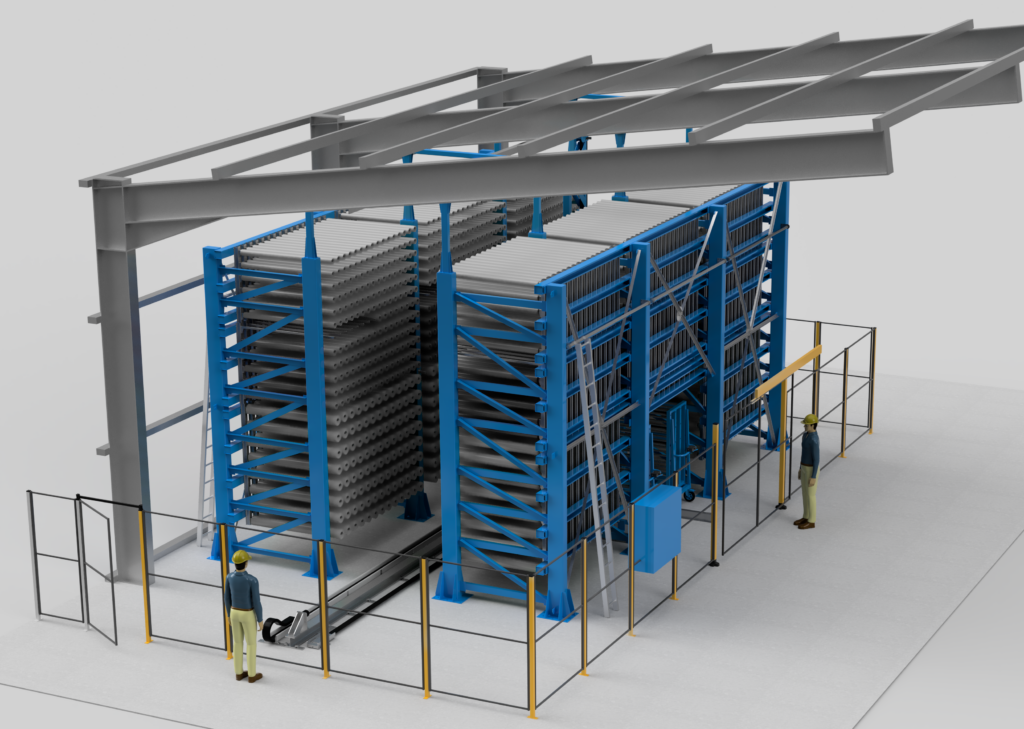

The Nepata Automated Roll Storage System (ARSS) is designed for small to medium roll storage with a total capacity of up to 3,000 rolls. In addition to the software-based optimization of processes, the system is characterized above all by the small footprint required for storing the rolls. In each case, the system is individually adapted to the customer’s requirements in terms of dimensions (footprint, height), total capacity and number of transfer stations.

How it Works

The roller storage system with vertical robot is based on a steel rack structure with horizontal mandrels on which the rollers hang very compactly. An automatic, vertical 3-axis robot sequentially moves to the rolls required for each job. Its specially designed tray gripper lifts the roll slightly from below, then lifts it down from the mandrel. The gripper then places the roll in a free transfer station. As soon as a roll is ready, the machine operator can manually open the transfer station like a drawer and remove the roll. The machines are ideally placed directly next to the transfer stations at the back of the storage system for optimal workflow. The storage of used rolls is done accordingly. For safety reasons, the robot warehouse is completely fenced in.

Automation of Film Logistics

The supplied software of the robotic storage system can be fully integrated into the well-known Nepata control software ConvertPlus. The provision of film rolls is triggered at an early stage via the production queues. The control software optimizes the storage locations of frequently used films in order to reduce travel distances. The automatic storage system also signals when a new roll of a material is needed. This can then also be set at a transfer station. On the software side, it is also controlled that those rolls are preferably used which are already older or optimal with regard to the remaining length, in order to avoid overaged rolls and too short remainders.

Benefits of ARSS

- Built for durability and up time

- Eliminate pick-up and drop-off times

- Maximize on-time delivery

- Reduce labor overhead and grow during period of skill labor shortages

- Increased work safety

- Optimize warehouse utilization and reduce overhead

ARSS Video Overview

The following link will provide with you a video overview of the World Premiere of the Automated Roll Storage System. Click here for ARSS video.

Additional Information

The Automated Roll Storage System is a fully customizable solution configured to the specifications of the customers application. To learn more, please feel free to call us at 734-668-0755 or email us at sales@supply55.com.

Take control of your converting and warehouse workflow today with ARSS from Supply55, Inc. and NEPATA GmbH.