What can you do to prevent wrinkled heat transfer appliques? Possible solutions include buying pre-shrunk tee-shirts or pre-pressing garments prior to heat pressing an applique. Read more »

Product news and information for the sign, screen and graphic arts trade

734-668-0755

What can you do to prevent wrinkled heat transfer appliques? Possible solutions include buying pre-shrunk tee-shirts or pre-pressing garments prior to heat pressing an applique. Read more »

Some screen printers, who print directly onto t-shirts or who print plastisol heat transfers, will stretch the garment before printing or heat pressing. By doing this, the weave of the shirt opens up allowing the ink to better penetrate the fibers of the fabric. This practice is believed to prevent cracking of the ink. Read more »

Troubleshooting Checklist If you are having problems cutting polyurethane heat transfer films, check the following possible causes: Read more »

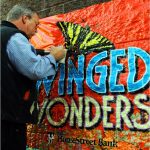

Getting good adhesion to painted wall surfaces has been a problem for sign makers and the manufacturers of vinyl films. Flat finish paints are especially a problem. To help your customer avoid the pitfalls that result in vinyl graphics falling off the wall, here are some guidelines to follow before beginning a wall graphics installation. Read more »

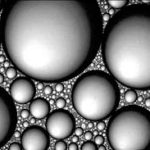

Have you ever seen the effects of outgassing paint on applied vinyl graphics? It’s not pretty. When the problem starts, it looks as if the surface of the film has had a breakout of severe acne. Tiny bubbles underneath the film grow until they merge together forming larger, more ominous bubbles. Read more »

Edge peeling usually makes every sign maker’s list of top vinyl problems. Failure to properly clean the substrate and failure to resqueegee the graphic after removing the application tape causes many edge lifting problems. While graphics installers often get blamed if a problem occurs, application mistakes aren’t the only reasons. Read more »

With the right film, the right application tools and the right techniques, vinyl graphics can be applied to textured wall surfaces such brick and concrete block. Many of old time decal applicators would heat a cast vinyl with an industrial heat gun, and burnish the hot, pliable film into the textured surface using a rivet […] Read more »

Applying vinyl graphics on vehicle surfaces with rivets is challenging for most sign makers. Vinyl failures to these surfaces are all too common. Here are some tips and procedures, used by professional decal installers, which will make these demanding applications easier and more trouble-free. Read more »

Sign makers should assume that many of their customers will do some pretty stupid things when cleaning graphics. For this reason they must provide the end user with instruction covering proper cleaning and care of any graphics. When I sold fleet graphics, many years ago, I would give my customers an instruction sheet which included the do’s and don’ts listed […] Read more »

Laminated vinyl material is still the most popular choice among sign makers for banner applications. A wide range of material is available for both outdoor and indoor applications. Read more »