Learn How You Should Prep Galvanized Steel and Rusted Surfaces Prior to Painting.

The key to any good paint job is good surface preparation. Preparing to paint steel surfaces requires special care.

Before sanding of the substrate, you must clean any oil or grease from the surface using a wax and grease remover and a final wipe down with alcohol. Most paint companies formulate their own solvent cleaner for removing grease and oil.

Trying to abrade the contaminant off of the substrate without cleaning the surface, only makes a bad situation worse. The reason is that by sanding a contaminated surface you only drive the contaminant into the old paint or metal pores.

Treating Rusted Surfaces.

Solvent cleaning will do nothing to remove rust from steel. Rust is the common name for iron oxide. It is like cancer. Once it starts, you need to kill it completely or it will continue to penetrate the metal causing more rust.

If a surface is rusted, the only way to eliminate it is to sand down to bare metal or sandblast the surface. The problem with trying to grind away rust is that the abrasive usually doesn’t get into the tiny pores of the metal, so it leaves some of the rust behind.

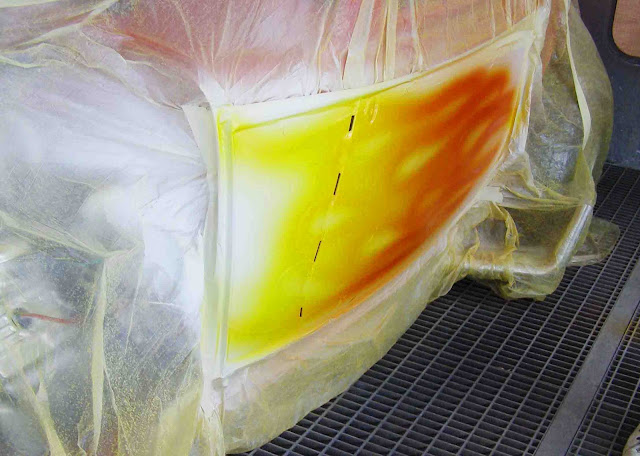

To dissolve the residual rust or to convert it into black oxide, automotive paint shops use an acid metal wash, which is a mixture of an acid, such as phosphoric acid, and glycol ether. The acid mixture not only cleans the metal, but also conditions it by chemically reacting with the metal to form a thin layer of zinc phosphate.

This protective layer prevents moisture from reacting with the steel or iron. Two of the commercial solutions used by automotive body shops that are formulated to etch rust are DuPont Quick-Prep and Sherwin-Williams Metal Prep.

After coating the bare metal surface with the metal prep, you should be good to go. However, many painters will take the additional steps of wiping the surface down with solvent cleaners.

When working with any type of acid, read the manufacturer’s Safety Data Sheet (SDS), technical bulletins and other related literature, before using the product. Always wear rubber gloves, safety goggles and other required personal protection equipment (PPE), when using acids.

Galvanized Steel.

Galvanized steel is a special case. It has a special protective coating of zinc that prevents rust. Here’s how this special coating works. Instead of the steel oxidizing and rusting, the zinc oxides instead. As the metal oxidizes, what is called “white rust” appears. Failure to remove this white rust will compromise the adhesion of the paint resulting in peeling. To get rid of the white rust you can use a wire brush or an abrasive pad.

After the zinc corrodes, the steel will inevitably rust. Painting the galvanized metal provides additional protection and improves its appearance. Before painting galvanized steel it must be primed.

New galvanized steel is one of the most difficult surfaces to paint. While the paint may initially stick to the surface, it eventually fails. It is just a matter of time.

The oily coating on new metal usually prevents good paint adhesion. This oily layer must be removed using a special solvent cleaner specified by the paint manufacturer.

Solvent cleaning alone is not sufficient. New galvanized metal is still a slick surface. To give the surface some tooth, you must then treat the surface using a cold phosphating pretreatment.

After treating the surface, it is ready for primer and paint. Standard paints used in the sign industry generally will not work. You must use primers and paints formulated specifically for galvanized steel.