Not all polyurethane heat transfer films are the same. That’s because some of these flex films aren’t 100% polyurethane, which are very flexible, and other heat transfer vinyl films are blends of polyurethane and vinyl. These blends are much stiffer that a pure polyurethane film.

100% polyurethane heat transfer films, because they are more stretchy, are a better choice for heat transfer graphics applied to a garment.

Plotter Cutter Tips.

Sometimes, though, that stretchiness can make plotter cutting a pure polyurethane film challenging. Here are a couple of tips to keep in mind when cutting polyurethane heat transfer vinyl films:

- Use a sharp plotter cutter blade. Ragged cuts indicate that it is time to change your blade.

- If the film is not cutting evenly, reduce the downforce pressure and slow the plotter cutter speed.

For more plotter cutter tips read Plotter Cutting Flex and Flock Films.

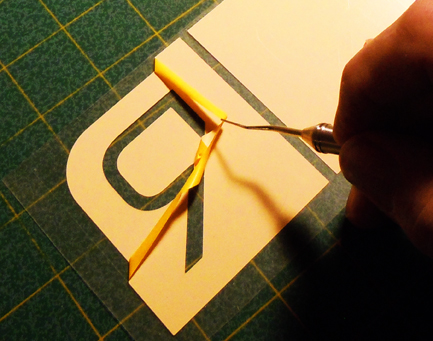

Weeding Tips.

- It sure helps if you can see what you are doing. Good lighting is essential when weeding any type of plotter cutter films. For detailed work, a magnifying hood is great for weeding an intricate design.

- Keep your work surface clean. Dispose of weeded heat transfer vinyl so you don’t end up with extraneous piece inadvertently stuck to the carrier of the applique and then heat pressed onto the garment.

- Using a good weeding tool will make weeding easier so you can be more productive. Everyone has a favorite tool. For some, Xacto knifes, air release tools, or tweezers are the tools of choice. Personally, I like the dental pick type of tool. Your sign supply distributor will have an assortment of weeding tools available for purchase.

- Pick the centers of the letters first, then weed the outside matrix.

- When weeding plotter cut heat transfer vinyl (reverse cut), start from the left side of the reading and work to the right. For printed and cut graphics that are right reading, work from the opposite direction.